德国PALAS UGF 2000气溶胶发生器

Liquid nebulizer with binary nozzle and cyclone (dp_max = 2 µm) as per VDI 3491-1 and -2

- 商品编号:德国PALAS UGF 2000气溶胶发生器

- 货 号:德国PALAS UGF 2000气溶胶法发生器

- 品 牌:Palas(成立年份,1983年.公司位置:卡尔斯鲁厄,德国.雇员,约50名受薪员工.出口百分比 约60%,随着过滤器测试系统和光学气溶胶光谱仪的开发和生产,Palas®是市场的领导者。 我们所有的产品都是在我们开发生产的,由Palas®在德国制造。 目前全球共有68项专利申请(05/05),我们不断开发我们的产品线。Palas®通过开发工作和实际应用,将其长期的专业知识纳入到粒子和过滤技术的安全标准的制定中。Palas®代表了多个ISO,DIN和VDI委员会。 主要内容有: 过滤器测试系统的标准;计量气溶胶测量装置的标准;校准计数气溶胶测量装置的标准;气溶胶生成指南.)

- 计量单位:台

- 市场价: ¥0.00

- 销售价: 面议

| 购买数量: |

|

- 收藏此商品

Description

The UGF 2000 aerosol generator is able to atomize liquids with a binary nozzle.

The UGF 2000 comprises an adjustable binary nozzle for adjustment of the desired mass flow and a cyclone. Unlike the AGF series, UGF 2000 has a cyclone with built-in control air. The control air is adjusted using a micrometer screw on a needle valve. By opening this valve, the aerosol concentration is able to be reduced by a factor of approx. 500 through the addition of control air. As a result, the generator is ideally suited for testing laminar flow boxes and clean rooms with low volume flow.

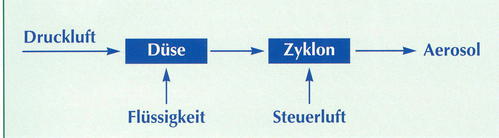

Fig. 1: UGF 2000 functional diagram

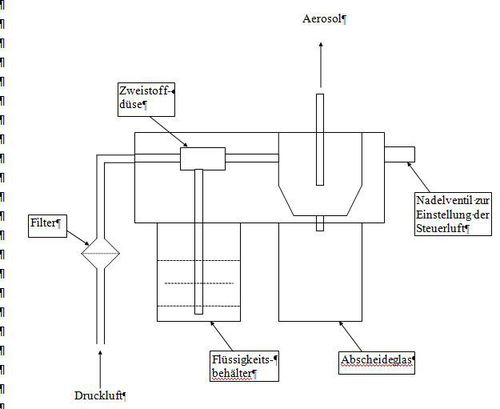

Fig. 2: UGF 2000 schematic diagram

The compressed air is supplied to a binary nozzle via a pneumatic on/off switch and an adjustable pressure regulator. The mist of droplets generated by the nozzle flows tangentially into a cyclone. Large particles are separated here by centrifugal force and drip into a separate reservoir. The remaining droplets leave the cyclone via the so-called “immersion tube”. The size spectrum of these droplets is determined on the one hand by the primary droplet spectrum generated by the nozzle, but especially by the separation characteristics of the cyclone on the other hand.

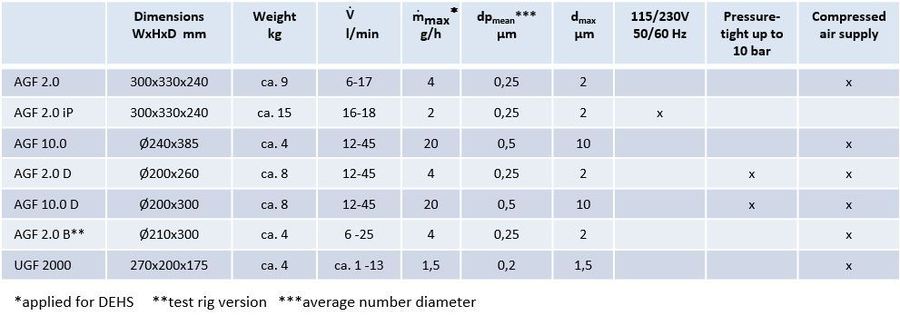

Table 1: Overview of the AGF and UGF systems

Benefits

dpmax in MPPS-range = 0.1 – 0.3 µm

Known and reproducible particle size distribution using a cyclone

Constant particle rate

Low particle concentration

Long dosing time

Variable particle concentration by a factor of 500 through adjustment of the primary pressure and control air

Compact, light, portable

Easy handling and solid construction

Datasheet

dpmax in MPPS-range = 0.1 – 0.3 µm

Known and reproducible particle size distribution using a cyclone

Constant particle rate

Low particle concentration

Long dosing time

Variable particle concentration by a factor of 500 through adjustment of the primary pressure and control air

Compact, light, portable

Easy handling and solid construction

Applications

Clean room technology:

HEPA/ULPA filter test

Acceptance tests and leak tests as per ISO 14644 and VDI 2083

Laminar flow boxes

Recovery tests

Filter testing, quality control:

Filter cartridges, filter media, particulate air filters for low volume flows and small filter surfaces

Smoke detector tests